The actual chromium plating process is a long one to describe. I will start with a little known fact about Chromium itself, then a brief on Decorative Chrome and finally Hard Chrome.

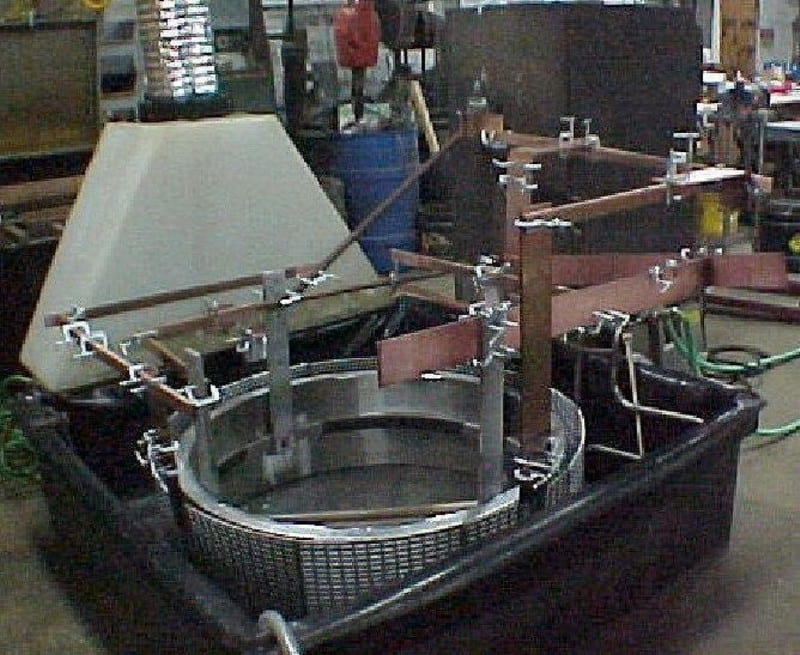

Chrome Plating is not as simple as 'just dipping it' in the solution. It is actually very complex as you can see from the picture. Learning how to do this properly takes years. However, it is very interesting and the journey from Apprentice to Platers Helper to HCP status is quite rewarding. Click on the Boxes to the right to learn about the various aspects.

Chrome plating has a ‘cracked’ structure. Not porous but, a fine lattice of cracks with no definite pattern. Because of this fine crack structure, it is a highly stressed deposit and must have this fine cracking to obtain its hardness. Thinner coatings (i.e., less than .001”) should be protected with light oil or wax for longer life.

Decorative Chrome Plating is actually a thicker (.0008/.0012”) Nickel plating followed by a thinner (.00001”) Chrome plating to protect the Nickel plating from pitting and peeling. Do not polish Decorative Chrome…just protect it with wax or light oil. The thin layer of chrome can be removed and will allow the nickel plating to be attacked, causing pitting & peeling.

Also, the ‘cracked’ structure will eventually allow moisture and contaminants to attack the Nickel. You will ruin your chrome plated items by polishing. It is as shiny as it is going to get. You may get a little bit better shine, but it will be short-lived. Keep wax or light oil on it and it will last many years.

Hard Chrome plating is somewhat different as it is used primarily for industrial purposes. Some call it “Industrial Chrome” or “Functional Chrome”. It is put on in thicknesses from .00001 up to .065”. It is possible to build up a diameter by .125” or 1/8”. The most common thicknesses being .0002/.0006” for anti-galling purposes and .001 to .002” minimum for wear applications. Thicker deposits are utilized for the build up of mismachined or worn parts. Also, thicker deposits are used in applications for harsh environments.

On a Knoop Hardness scale, a diamond is a ‘10’, and Chromium is a ‘9’. Few materials can come close to this. A chrome plated part is a better part and will last longer due to the hardness of Chrome. It also has a very low coefficient of friction…almost nothing will stick to it—another excellent property.

Adding ‘True’ Hardness to a Surface:

With a minimum of .001” thickness on a part…you can take a file to it & you will dull the file and not cut through the chrome. Anything less than .001” thick, and you can cut through it rather easily. Keep this in mind when specifying how much chrome you require for your application. When in doubt, ask your plater. They should be able to give you guidance on the thickness required for what you are trying to accomplish.

Thinner deposits are utilized for Appearance, Anti-galling, and Lubricity. They should never be specified for a wear application unless special conditions dictate. i.e. You need added life but can not tolerate a larger amount of chrome due to size restrictions. Or the plated surface is an impact zone.

Thin ‘Dense’ Deposits:

Thin Dense Chrome may be dense, but it is still thin. Take a file to any of these trade named products, and you will cut right through it. And the Hardness claims…have it tested…we did. It is no harder and, in most cases, softer than any regular (no trade name) Hard Chrome. Any experienced Hard Chrome shop can provide thin dense chrome plating that is comparable and probably better…at a much less expensive price. Why pay extra for a trade name?

'Crack Free' Deposits:

These deposits are of the same genre as the Thin Dense Deposits described above. These deposits yield a greater degree of corrosion resistance due to their 'Crack Free' structure. However, in order to accomplish these structures, they do not have the same high hardness as regular deposits and consequently will not last as long in wear applications.

Other Types of Deposits:

Other types of deposits are Porous Chrome, and Channel Chromium used mainly for oil retention in cylinders and on crankshafts. Black Chromium is used mainly for its appearance.

Engineering the proper thickness for a new part can be tricky. Consultation with an expert is recommended. Sometimes ‘trial and error’ must be performed to reach optimum performance/cost ratios. An expert can help avoid mistakes and expedite your experimental stage.

On worn or mismachined parts, the thickness is normally determined by the amount of damage to be removed before plating and the amount that the part is undersized (outside diameter) or oversize (inside diameter).

When specifying thickness for a part that will require grinding after plating, always specify .005” total under (or .0025” on a side) size Before Plating. This will insure that you have the minimum of .001” thick for wear in case the part is set up slightly off-center when grinding After Plating. Also, there is a tremendous amount of heat generated at the grinding zone, even with plenty of coolant. Thinner deposits can ‘lift’ during grinding because of this heat. If it should be necessary to grind a thinner deposit…great care must be taken.

When grinding chrome deposits, certain precautions and instructions are imperative. Use ONLY an Aluminum Oxide wheel. Manufacturer’s can offer recommendations – Norton Company is a good source and, in our opinion, makes the best wheels. Always grind with plenty of coolant. Never dry.

Chrome plating does not apply evenly on most surfaces, especially true in thicker deposits, requiring grinding after plating (AP). Find the ‘high spots’ around keyways and edges - Click on:

Table of Characteristics of Chrome Deposits for examples. Always remove these 'high spots' first, with a hand grinder or with the machine wheel very carefully. It is important to use an indicator and/or micrometer to find the high spots on the chromed area. This will help avoid ‘burning’ the Chromium by taking too deep a cut, accidentally. Deep cuts ruin the chrome plating and it will lose its properties and adhesion. When final grinding on the main body of the part, depth of cut should not exceed .0002”. The slower, the better.

Grinding chrome is very unlike grinding steel and other metals and coatings. There should be no ‘sparks’. Find and use a waterproof marker to apply to the chrome surface to be ground. Because there is no spark, this will aid you in determining when and where the wheel is touching the plating. Grinding chrome is a very slow and tedious process. On average, it will take 2 to 4 times longer to grind chrome deposits compared to steel.

Chrome Plating is not as simple as 'just dipping it' in the solution. It is actually very complex, as you can see from the picture. Learning how to do this properly takes years. However, it is very interesting, and the journey from Apprentice to Platers Helper to HCP status is quite rewarding.

The process of electrolysis accomplishes chromium plating. Utilizing DC current at a specified voltage and amperage, you have a Cathode, which is negative (the part to be plated) and an Anode, which is Positive. The Cathode is placed at a predetermined distance from the anode in the electrolyte (the solution), and the current is applied. The amount of time the Cathode (part) is left in this condition will determine the thickness.

Masking:

Various different types of masking are utilized to stop off on areas that do not require plating—tapes, plugs, shields, special lacquers, etc. A good plater knows what to use, so just tell them what you do not want to be plated. Or just tell them what is to be plated. They will figure out the rest. If not, they will contact you for clarification.

Lets Chrome Plate Something:

After a part arrives in the plating plant, it goes through Incoming Inspection. Verifying count, condition of material, and figuring out where and how much plating is to be applied, are some of the areas covered.

Once this is determined, it will be masked off for abrasive blasting to ensure the area to be plated is very, very clean. After blasting, the area is kept protected so as not to form any oxides on the surface. It must not be touched by anything from this point onward.

The part is then masked and racked for plating. Very expensive tapes (some costing as much as $60 a roll at this writing), lacquers, shields, plugs, etc. are used. Knowing what and where to apply these takes years of knowledge to master properly.

After masking, an electrode or anode has to found or fabricated to conform to the configuration of what you are plating. This is also a crucial step in the process and requires years of knowledge to fabricate properly.

The part must now be racked for introduction into the plating bath. Again, this takes years to learn properly in order to obtain the desired results. Make sure your plater has significant experience in the business. The best Hard Chrome operations do not get involved in other types of plating. Hard Chrome is complicated and takes all of one's resources to do a good job, consistently.

Actual Plating:

We are now ready to place the part in the plating solution. In-Process Inspection is required at this time. The Plating Bath 'make up' ingredients are verified, as well as temperature, voltage, amperage, and anode to cathode spacing. All electrical contacts are cleaned to ensure proper transfer of current. Proper execution on how all these are adjusted also takes years to learn.

The part is now reverse current etched for final cleaning and activation of the surface. This ensures proper adhesion in that you not only have a mechanical bond but a molecular bond. Knowing how long and at what current valuations is critical.

The part is placed in plating position, and the actual plating commences. The proper voltage and amperage is adjusted on the DC power supply.

The plating rate is now determined, and the part is allowed to remain in the solution for the proper duration to obtain the required build-up of chrome. Plating rates are very slow for Hard Chrome plating. Generally in the neighborhood of .001" per hour. Faster rates are possible with our proprietary process. The Jersey Chrome hard chrome process is superior in not only plating rate but hardness and other properties of the deposit.

The part must be attended to during the plating process. 'Trees', solution level, and monitoring of all values previously mentioned are very important. One small detail left unattended, and you will have to strip the part and start all over again. This is one reason it is difficult for your plater to give you a delivery date...things go wrong, and the delivery date has to be pushed back due to reprocessing. Use a plater that has the proper experience and you will eliminate delays and missed deliveries. Jersey Chrome's on time delivery is 99.9%.

After plating, the part must be inspected, unracked, masking removed, and then rinsed and cleaned. This also can take considerable time, as the masking is very durable, being able to withstand acid solutions at high temperatures. They sometimes must endure plating cycles of 48 hours or more for heavy build-ups.

Final Inspection is made to verify plating thickness, visual on the chrome and part condition, proper cleaning, etc.

The Surface Roughness of the as plated deposit is very dependent upon the surface condition before plating. Chromium plating will magnify the surface. It does not go on like 'body putty'. Small imperfections will not cover up and actually will become larger & more visible—the thicker the plating, the larger the magnification. For example, a 32 RMS finish will end up as a 32 with thinner deposits but will magnify to a 36 or 40 if over .003" thickness is applied. A pencil point hole or porosity will end up much larger and will not fill in or cover up. Click on: Table of Characteristics of Chrome Deposits for an example. As a general rule: Supply or specify a surface before plating that is as good as or better than you would like to end up with after plating.

Trying to obtain a specific RMS that is 'rough' after parts are ground to size can be problematic. Sometimes it can be obtained by using rough Al Oxide grit. Chrome is easy to obtain a great finish on. A 16 RMS is as ground and can be polished rather easily down to a 4 or even 1 RMS.